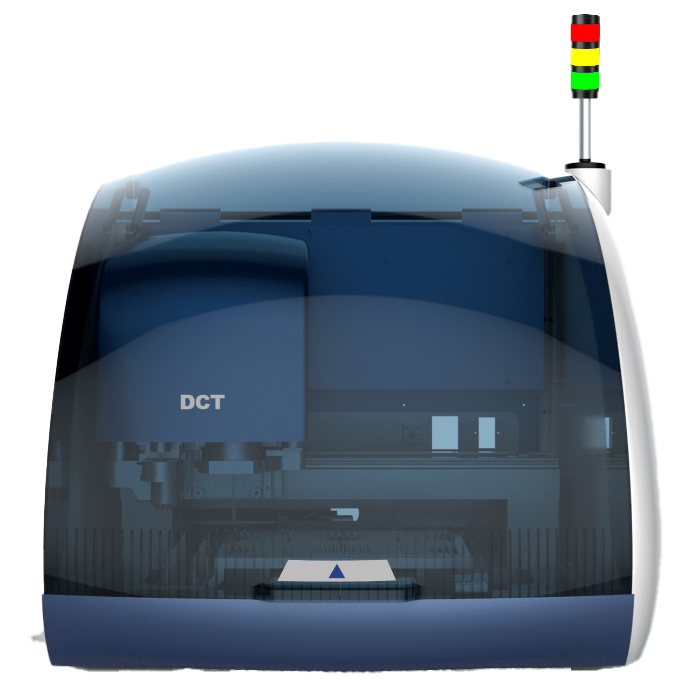

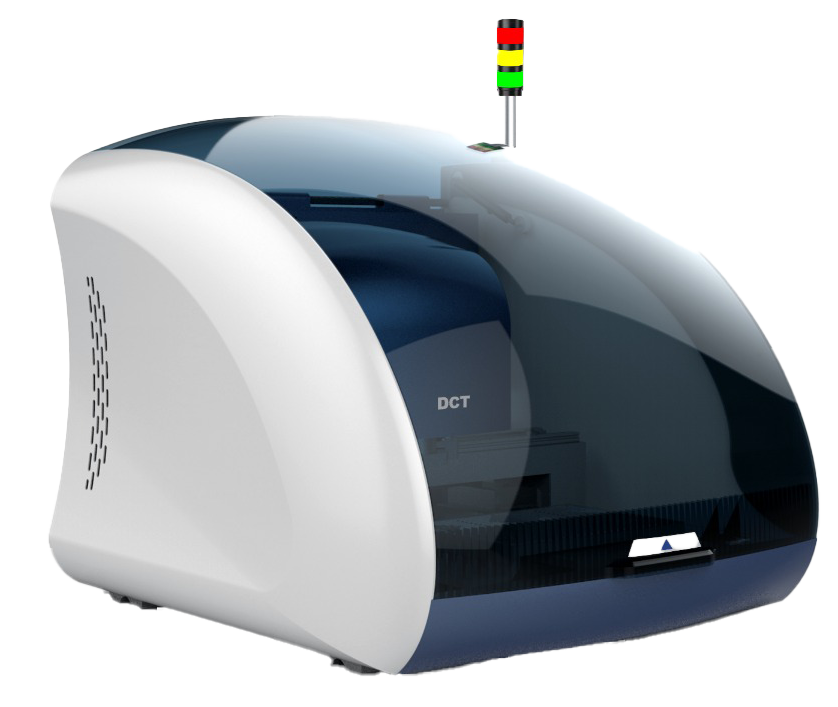

The DCT HybriDo system has ushered in a new era of PCB prototyping in the laboratory. The combination of laser and mechanical advantages makes in-house PCB prototyping much easier. Track drilling, routing and engraving can all be carried out in a matter of minutes with a single machine.

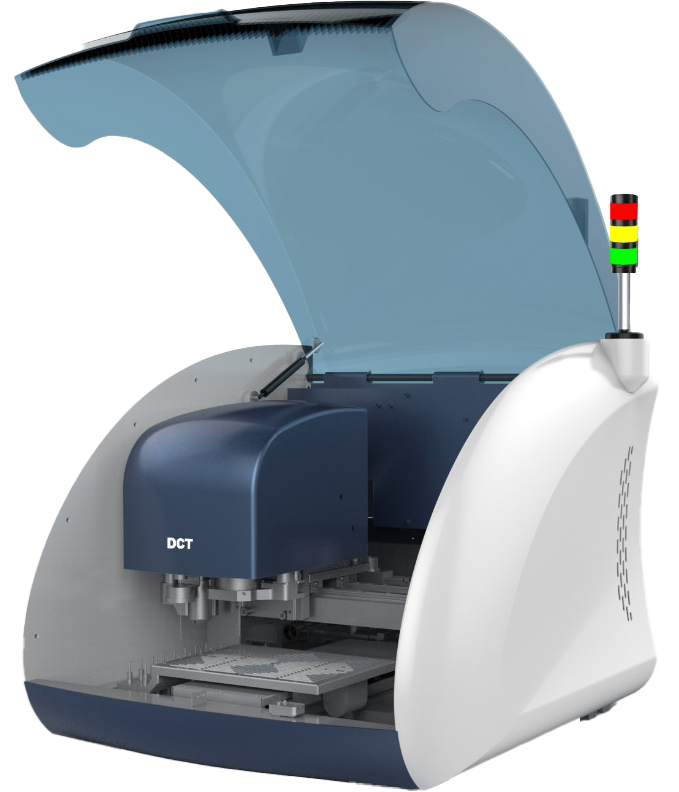

The HybriDo is equipped with a high-performance German spindle. A servomotor on all axes and a fully automatic 16-tool tool changer guarantee very fast drilling and milling speeds. The integrated vision system can share the exact position of the laser system. As the drilling and engraving process is shared with the same vision and positioning system, maximum precision can be guaranteed.

Thanks to DCT's patented S&S chemical-free process, printed circuit boards can be produced in just a few minutes without burning the substrate material. RF and microwave circuits, in particular, benefit from precise dimensions and perfectly clean edges, enabling the circuit to be perfectly matched to simulation results. Thanks to the vacuum table, flexible materials can be positioned and held freely. HybriDo is also suitable for FPC or multilayer printed circuit boards..

With its powerful CircuitCAM data processing software, DreamCreaTor driver software and your PCB design software, creating and prototyping your printed circuit boards becomes fast and easy!

Excellent combination of laser and mechanical treatments

- Excellent combination of laser and mechanical treatments

- Faster, finer laser engraving of printed circuit boards

- High-performance drilling and milling with 80,000 rpm spindle Made in Germany

- Fully automatic tool change, with 16 tool stations

- State-of-the-art motion system with servomotor, mechanical resolution and maximum precision

- Granite base for maximum precision and robustness

- Compact and powerful

Mechanical

Drilling

laser

Milling

Mechanical

Routing

TECHNICAL SPECIFICATIONS

- Min. line width: 0.1mm (depends on material).

- Min. line spacing: 0.05mm (depending on material) .

- Processing speed: 12cm²/min (material-dependent) .

- Min. drilling diameter: 0.2mm.

- System repeatability: ≤± 2μm.

- Displacement control resolution: 0.5μm.

- Tool changer: 16 tool bases with automatic changer.

- X Y axis travel speed: 150mm/s.

- Drilling speed: 120 /s.

- Routing speed: 5mm/s (depending on material and thickness) .

- Vitesse de rotation de la broche: 80,000 tr/min

- Laser wavelength: 1064nm Fiber laser.

- Laser power: 30W.

- Axis driver: X,Y,Z axes controlled by Servomotor.

- Power supply: 220VAC 50Hz, 1600w.

- Compressed air supply: Min. 6 bar; 80 L/min @ 6 bar.

- Dimensions (W x H x D): 880mm x 800 mm x 961 mm (without light turret).

- Weight: 120 kg

CONFIGURATION & OPTION

- Automatic vision and positioning system: Standard

- Vacuum table: Standard

- Axis protection: Standard

- Measurement of quadratic elements (basic function): Standard

- CircuitCAM data processing software: Standard

- DreamCreaTor machine control software (HMI): Standard

- Edwin PCB design software: Standard

- Silent external extraction/filtration: Standard

- Compressed air: Option

- Laser safety goggles: Option

- PC: Standard