The KAYO A6L is an automatic SMD report station.

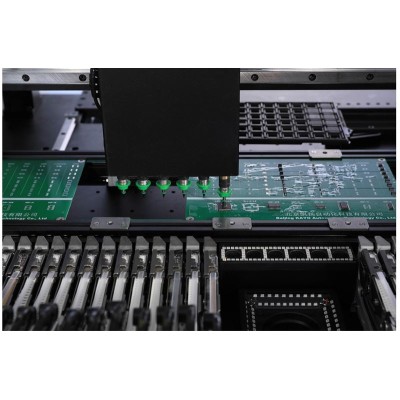

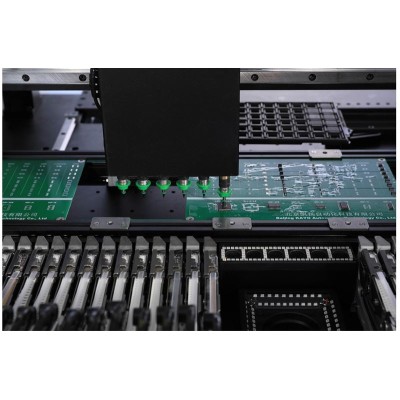

Compact it can accommodate 60 tape feeders as well as 8 placement and positioning cameras. The placement accuracy is 0.01 mm for a placement capacity of 13000 components per hour(max).

Quick to set up and easy to handle, the KAYO A6L Pick & Place is the ideal machine for the assembly of your SMD series.

Features

- The machine is delivered with 8 cameras : 1 for the detection of the sights, 6 cameras for the mounting nozzles and 1 high precision camera

- Camera refocusing & detection of rejection marks

- Installation capacity of 13000 components / hour (max) with an accuracy of ± 0.01 mm

- Works under Windows® environment

- The drivers have been optimized to guarantee quick component placement while improving precision and a low noise level

- An automatic card transit system within the machine in three sections saves time and efficiency

|

Feeder No. |

60 |

|

Mounting Heads |

6 |

|

Average Power |

600W |

|

Positioning Accuracy |

0.01mm |

|

Nozzle Buffering Range |

5.0mm |

|

Power Supply |

220V, 50Hz |

|

Compressed Air |

0.5-06Mpa |

|

Driving Motor |

Panasonic servo motor |

|

Recognition Method |

Six heads recognize synchronously |

|

Nozzle Vacuum Source |

High-speed on-off vacuum generator with vacuum damage |

|

Max. Circuit Board Area |

650x370mm |

|

XY Max. Movement Range |

700x619mm |

|

Z Axis Max. Movement Range |

20mm |

|

Belt Type Feeder |

8/12/16/24mm feeders, stick feeder, tube chip |

|

Max. Mounting Speed |

13000CPH |

|

Average Mounting Speed |

10000CPH (Visual) |

|

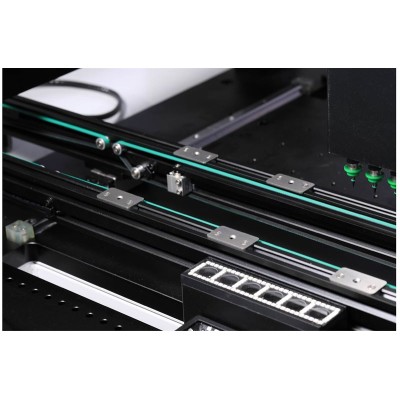

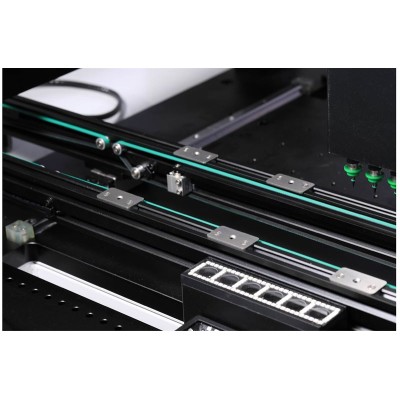

XYZ Drive Guide Rail |

TBI High-precision heavy-duty straight-line guide rail |

|

Motion Drive System |

Panasonic High speed DPS driver |

|

Operating System |

Support Windows XP, Win7 operating system |

|

Component Angle |

0~360°, synchronized rotation in motion |

|

X/Y Running Mode |

Imported TBI high-precision ball screw rod + imported TBI heavy-duty linear guide |

|

Mark Point Positioning |

Full automation |

|

Intelligent Alarm |

Automatic correction and supplement, alarm when materials shortage |

|

Board Input Method |

Three-section transmitting boards-automatic connection from left to right, automatic PCB transmission positioning |

|

Visual Display |

15" industrial control display ratio 4:3, resolution 1024X768 |

|

Programming Mode |

Point-to-point programming, visual programming, PCB file coordinates inputting, etc. |

|

Recognition Camera No. |

1 Mark recognition camera, 6 high speed recognition camera, 1 high-precision recognition camera |

|

Applicable Mounting Range: |

Suitable for 0402, 0603, 0805, 1206, LED lamp beads, diodes, transistors, SOT, 40mm*40mm range pin pitch ≥0.3mm QFP, BGA etc. |

|

Dimensions |

1335x1230x1420mm |

|

Product Weight |

500KGS |

Delivered complete with double PC, software, start-up kit and 1st year maintenance kit, feeders are extra